Yoshida Hamono is a family-owned Japanese company with an age-long tradition in manufacturing state-of-the-art tools and Japanese swords (katanas) by hand. Yoshida Hamono has a great deal of experience forging ZDP-189 steel in the traditional manner. The company has a workshop in the Japanese town of Saga. It is well-known for manufacturing metal products in tested corrosion-resistant materials, such as VG-10, Ginsan and Swedish steel. A typical Yoshida knife has a beautiful Damascus pattern and an uneven upper surface of the blade, full of small dents, which are results of hand-forging.

We visited Yoshida Hamono during the cherry blossom season in spring 2016 and in 2018 to learn about their craft. We were especially curious to learn about the manufacturing process of the knife we designed here at SharpEdge, the famous ZDP-189 Bunka. We've learned about the history of Yoshida Hamono and took some pictures, posted at the end of this article. 🔪 🇯🇵 🎎

See our collection of Yoshida Hamono knives.

The story of the blacksmith family Osamu Yoshida and ZDP-189

The history of Yoshida knife begins with its founder Seiji Yoshida. He started out as an apprentice to masters Hideyoshi Muto, a prestigious blacksmith in the Japanese sword making, and Kensaku Motomura, a maker of military swords for the Japanese army. In 1943, Seiji was awarded the Newcomer Award at the Japanese Sword Exhibition, which further urged him to improve. Under the supervision of his father Nobuichi and together with other talented families he established the Yoshida Knife Factory. It was ranked number one in Kyushu and was the prototype of the present Yoshida Knife Co., Ltd. Seiji acquired his broad knowledge of knife-making by learning the traditional skills of the workers and by studying the theory of blacksmith techniques. The confirmation of his diligent efforts are the ZDP-189 knives.

As ZDP-189 is the finest stainless steel material, manufactured by the leading Japanese steel manufacturer "Hitachi Metals", the blade is hard, the sustainability of the sharpness is excellent, and, in addition, its great feature is that it is extremely hard to rust. ZDP-189 fabrication was very difficult and the training consisted of repeated trial and error. Still, through the years, Yoshida Hamono managed to introduce the sub-zero treatment in its production, making the ZDP-189 knife what it is today – a synonym for high quality, extreme sharpness, and hardness.

Photo story of our visit

Beautiful spring day outside of the Yoshida Hamono smithy.

Inside of the workshop.

The master carefully developed the plan for treating ZDP-189 steel in accordance with the guidelines of the manufacturer, Yasugi Specialty Steel, a subsidiary of the well-known steel company Hitachi Metal, and continued to improve this method based on his experience gained over years of working with this steel.

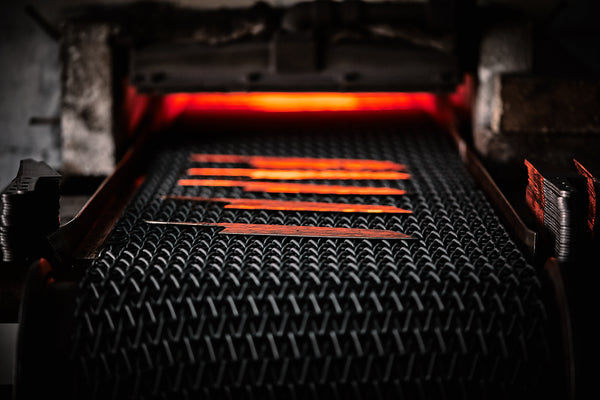

The process begins by heating the laminate, which has been prepared in advance. Laminating ZDP-189 steel is a very demanding process; therefore master Osamu-san first prepares one common laminate on large presses and cuts it into smaller pieces before treating it.

By correctly forging the steel, he adjusts the size of the particles therein, which makes the steel more homogeneous and gives the final product a finer sharpness. A knife made by forging is significantly stronger than a knife that has been cut because the flow of particles remains continuous. The forging starts by alternating heating and treatment of the steel with large pneumatic hammers.

In the final stages of the process, increasingly more hand forging is involved and the final impressions of master Osamu’s forging are visible on the blade.

Heat treatment considerably influences the properties of steel. Thermally treating ZDP-189 steel is very demanding due to the fact that extreme precision as to the temperature and timing of heating and cooling is required.

First, rapid cooling in oil is required, and then the blade is inserted into a press in order to reduce certain stresses. Slow heat treatment reduces the tension in metal, achieves a more homogeneous carbide distribution, and ensures a more robust blade.

Cooling in liquid nitrogen (-196℃).

Furnace and temperature control. Controlled and gradual warming to room temperature is needed.

Heat treatment produces steel with a hardness of 65-67 HRC.

Next step: sharpening of the blade.

Attaching a traditional Japanese handle made from palisander, i.e. rosewood.